Porotherm clay bricks are horizontally or vertically perforated clay bricks. They are manufactured in a variety of sizes (common size is 400x200x200 mm) from natural clay. The term porotherm is used for this type of brick due to its desired thermal insulation characteristics. The perforation of the clay brick provides an exceptional walling system which facilitates thermal insulation resulting in cooler interiors in hot seasons and warm interior conditions in cold seasons.

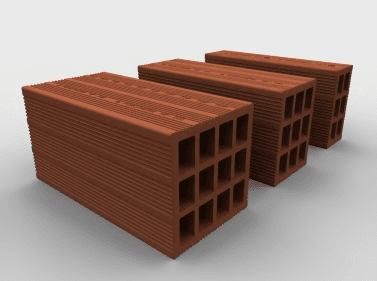

Fig 1. Horizontally Perforated (HP) Brick

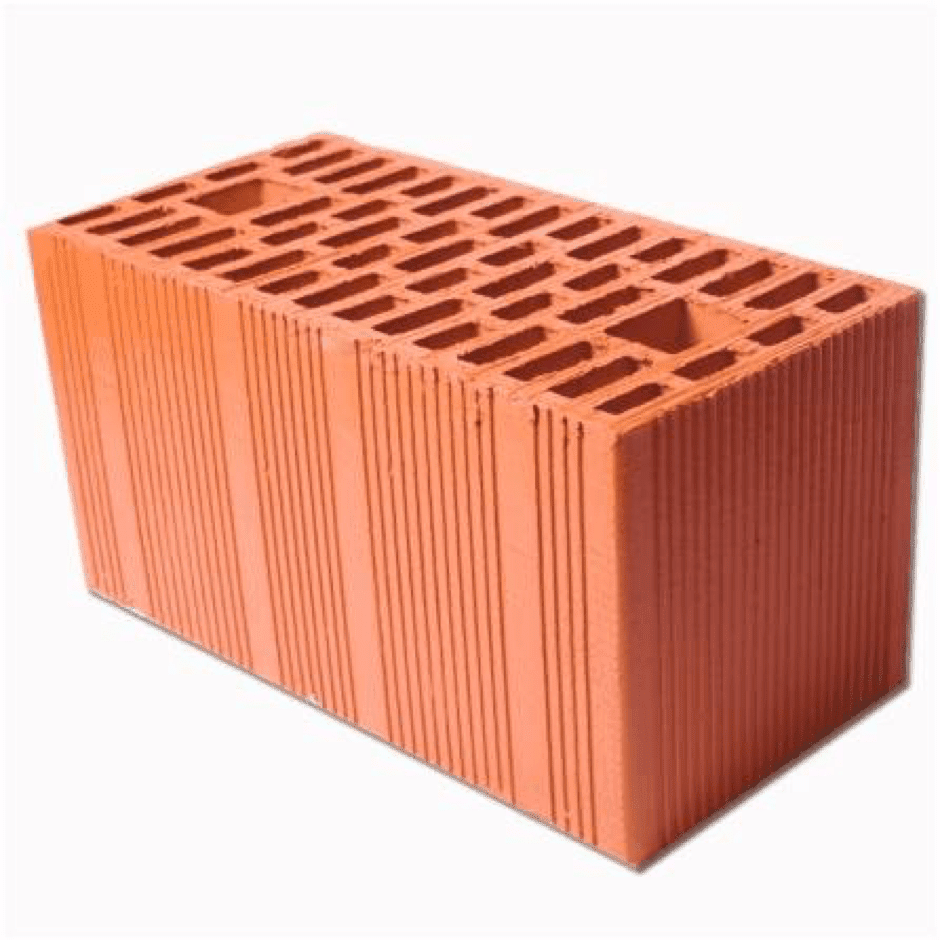

Fig 2. Vertically Perforated (VP) Brick

The porotherm clay bricks are easy to use, economical, environmentally friendly, and it can be used for the construction of both non-load bearing walls and load bearing walls. The porotherm bricks are low weight, durable, strong, and possess a satisfactory fire resistance. It can be used with dry mortar which eliminates the need for curing time.

Properties of Porotherm Bricks

- The compressive strength is greater than 3.5MPa

- High thermal and sound insulation.

- Low weight: it is lighter than traditional solid concrete block by 60 percent.High fire resistance

- Density range from 694 to 783 kg/m3

- Large in size but light in weight results in low dead load

- Water absorption is around 15

Advantages of Porotherm Bricks

1. Good Strength

The compressive strength of porotherm brick is greater than 3.5MPa. The application of high temperature during its manufacturing process and the present of terracotta material in its composition gives the material excellent strength.

2. Thermal Insulation

Porotherm bricks have great thermal insulation which is obtained due to the perforation of the bricks.

3. High Durability

The high compressive strength, fire resistance, and resistance against carbonation makes porotherm bricks highly durable and has a long life span. Water absorption is around 15% that is why the risk of dampness, cracks or shrinkage of walls are substantially low.

4. Cost-effective

Not only does the porotherm bricks save a lot of energy but also cut construction and operation cost. The usage of this type of brick would eliminate the need for using AC in summer and heaters in winter, hence save energy. It does not require sand and cement for wall construction, hence it cut construction cost. Finally, it has zero maintenance cost.

5. Environmentally Friendly

The porotherm bricks have recycled content. Due to the fact that chemical materials are not used in its composition, so it would not cause allergic issues.

6. Speed of Construction

Wall construction speed increases substantially when porotherm bricks are used. This is due to brick lightweight, ease of handling, and elimination of curing time since sand and cement is not needed for the construction of porotherm brick walls.

Additionally, it can be cut and chisel easily which makes fixture installation much easier. Finally, porotherm ensure a clean and dry work site that is why it leaves no debris to be disposed of.

Fig 3. Load bearing porotherm brick

Applications of Porotherm Bricks

- Load bearing and non-load bearing wall constructions.

- Partition wall

- Infill panels within framed structures.

- Single leaf or monolithic internal and external walls.

- Inner leaf of brick-faced cavity walls.

- Inner and outer leaves of rendered cavity walls.